-

Sale!

Hindu Religious Statue of Adiyogi for Car Dashboard

₹2,999.00Original price was: ₹2,999.00.₹1,499.00Current price is: ₹1,499.00. Add to cart -

Sale!

Garage Key Holder with Random OG Hotwheels (Car not included)

₹899.00Original price was: ₹899.00.₹599.00Current price is: ₹599.00. Add to cart -

Sale!

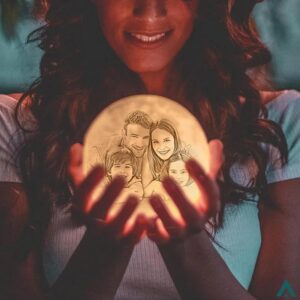

3D Printed Moon Lamp – Customised

₹600.00Original price was: ₹600.00.₹400.00Current price is: ₹400.00. Add to cart

FDM vs SLA: Choosing the Right 3D Printing Technology

Introduction: What is FDM and SLA?

Have you ever been stuck choosing between two good options—like pizza vs. burger—where both satisfy your craving, but only one truly fits the moment? That’s exactly how many makers and businesses feel when deciding between FDM vs SLA 3D printing.

Both are powerful technologies, but the wrong choice could leave you with wasted time, higher costs, and a product that just doesn’t deliver. So, let’s break down what these two are, where they shine, and how you can confidently choose the right one for your next project.3D printing materials

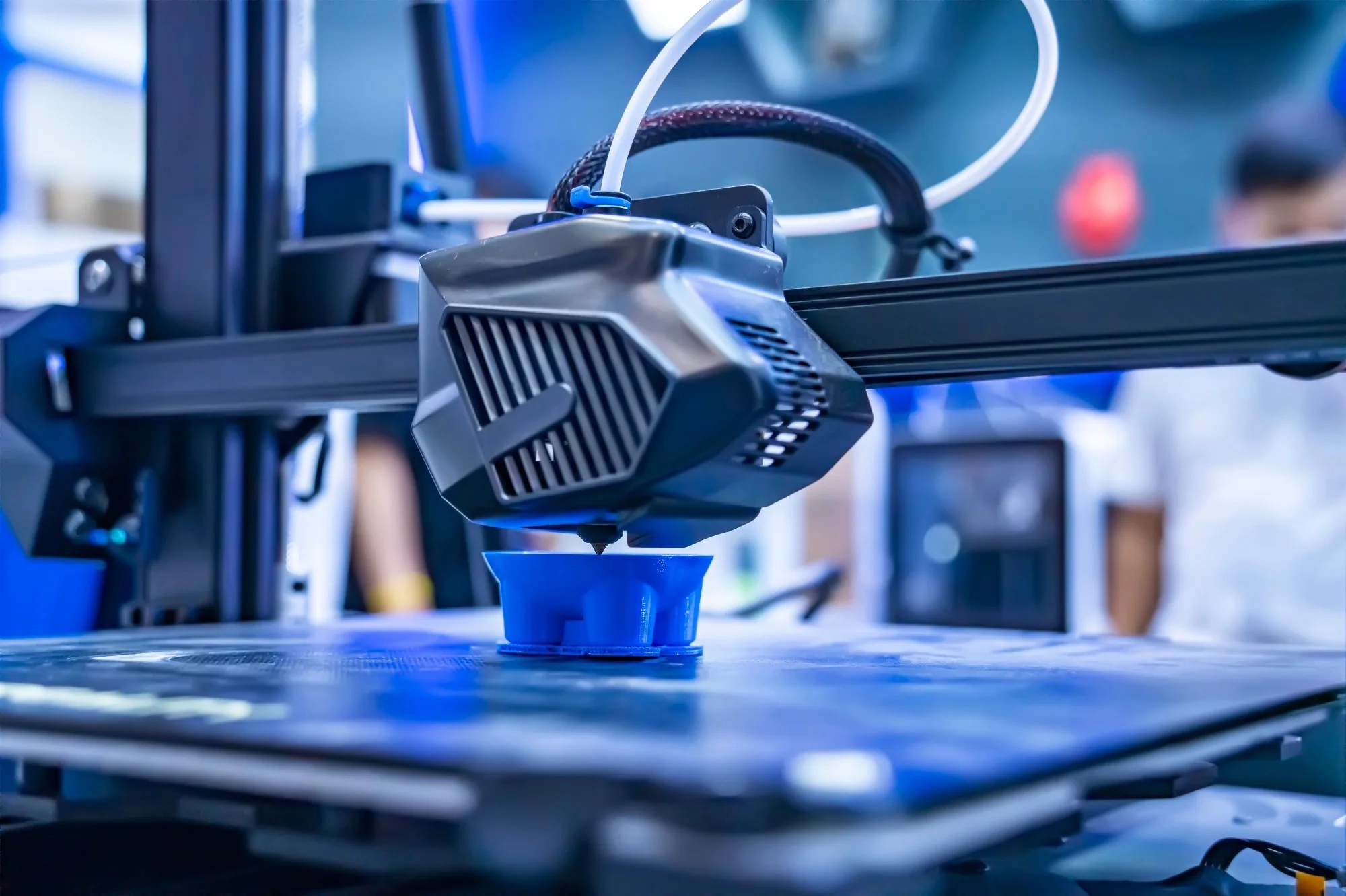

How FDM Works and Its Benefits

FDM, or Fused Deposition Modeling, is the most widely known 3D printing method. Imagine a hot glue gun that layers melted filament one line at a time until it builds your part.

Benefits of FDM Printing:

-

✅ Affordable & Accessible – Perfect for beginners or budget-conscious businesses.

-

✅ Fast Prototyping – Get a part in hours, not days.

-

✅ Wide Material Choices – From PLA to ABS to advanced filaments like PETG and Nylon.

-

✅ Durable Prints – Strong enough for functional prototypes and end-use parts.

Think of FDM as your everyday reliable workhorse. If you need something quick, sturdy, and cost-efficient, FDM printing is your go-to.

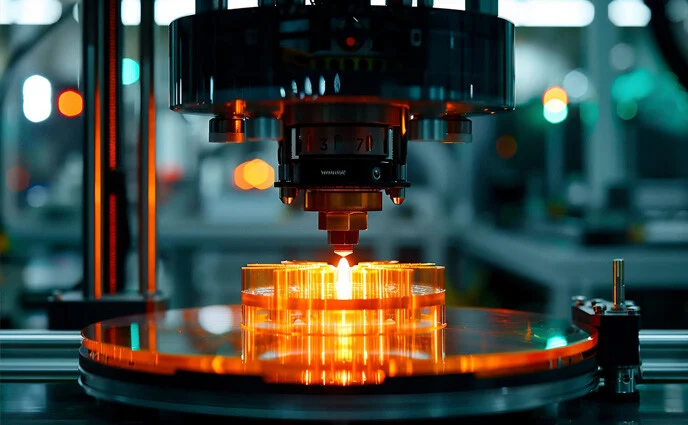

How SLA Works and Its Benefits

SLA, or Stereolithography, is a little more like magic. Instead of melting filament, it uses UV lasers to cure liquid resin layer by layer into solid parts.

Benefits of SLA Printing:

-

✅ Insane Detail – Perfect for miniatures, jewelry, and dental models.

-

✅ Smooth Surfaces – Minimal layer lines compared to FDM.

-

✅ Functional Resins – Options include flexible, castable, and biocompatible resins.

-

✅ Precision Fit – Great for engineering applications where accuracy matters.

If FDM is the workhorse, SLA is the artist. It’s the choice when aesthetics and detail are more important than speed or cost.

Material Compatibility

One of the biggest differences in FDM vs SLA 3D printing is the materials:

-

FDM Materials: PLA, ABS, PETG, Nylon, TPU (flexible), Carbon Fiber blends.

-

SLA Materials: Standard resin, castable resin, flexible resin, dental-grade resins, engineering resins.

👉 Simply put: if you need toughness and a wide material range, FDM wins. If you need ultra-detail and specialty finishes, SLA takes the crown.

Cost and Efficiency Comparison

Here’s the truth—budget matters.

-

FDM Printers: Lower cost machines (₹20,000 to ₹2,00,000). Filament is also cheap (₹1,000–₹3,000 per kg). Great for mass prototyping.

-

SLA Printers: Higher upfront cost (₹40,000 to ₹5,00,000). Resin costs more (₹4,000–₹10,000 per liter). Plus, post-processing adds time and effort.

👉 Efficiency Tip: If your business needs dozens of prototypes quickly, FDM saves money. If you need one flawless, detailed part—SLA justifies the investment.3D printing

Use Cases: Which Projects Suit Which Technology?

Here’s where FDM vs SLA becomes clear.

-

FDM Best For:

-

Functional prototypes

-

Large models

-

Everyday objects

-

Engineering test parts

-

Educational projects

-

-

SLA Best For:

-

Jewelry & fashion prototypes

-

Dental and medical models

-

Miniatures & collectibles

-

Smooth display-ready models

-

High-precision engineering fits

-

Example scenario:

Ramesh, a Chennai-based product designer, needed strong prototype housings for an electronics project. He used FDM printing in Chennai for fast, low-cost models. Later, when he wanted a polished version to pitch to investors, he switched to SLA printing in Chennai for smooth, presentation-ready prototypes.

Conclusion: Making the Right Technology Choice

Choosing between FDM vs SLA 3D printing isn’t about which is “better”—it’s about which fits your project’s needs.

-

Need affordable, durable, quick-turn prototypes? Go with FDM 3D printing in Chennai.

-

Need high-detail, smooth, precise parts? SLA printing is the winner.

At Arsene 3D, we provide both FDM and SLA printing along with 3D Designing, Filaments, and Prototyping Services. Whether you’re an individual tinkering at home or a business ready to launch, we’ll guide you to the best choice.

📞 Call/WhatsApp us at +91 96295 95638

📧 Email: sales@arsene3d.com

👉 Explore more on our socials:

Your project deserves the right technology. Let’s print your ideas into reality!