The success of 3D printing depends heavily on the materials used. 3D printing materials determine the strength, flexibility, durability, and overall functionality of the final product. From hobbyists using 3D printer services in Chennai to industrial applications worldwide, choosing the right material is crucial for every 3D printing project.

1. Plastics: The Most Common 3D Printing Materials

Plastics are the backbone of 3D printing technology, widely used by both beginners and professionals. Their versatility and low cost make them ideal for prototypes, models, and functional parts.

Some popular types include:

1.1 PLA (Polylactic Acid)

PLA is a biodegradable thermoplastic made from renewable resources like corn starch. It’s one of the easiest materials to print with and is often recommended for beginners using 3D printers. 3D printing near me shops often stock PLA due to its popularity.

1.2 ABS (Acrylonitrile Butadiene Styrene)

ABS is stronger and more heat-resistant than PLA. It’s ideal for functional parts like casings and automotive components. Many 3D printer services near me provide ABS printing because of its industrial applications.

1.3 PETG (Polyethylene Terephthalate Glycol)

PETG combines strength, flexibility, and chemical resistance. It’s suitable for water-resistant parts and functional prototypes. Online platforms for 3D print online often offer PETG as a standard option.

1.4 Nylon

Nylon is highly durable, flexible, and abrasion-resistant. It is commonly used in mechanical parts, gears, and wearable items. 3D printing Chennai services often recommend nylon for demanding applications.

2. Metals in 3D Printing

Metal 3D printing materials are used in industries requiring high strength, durability, and precision. Metal additive manufacturing is prevalent in aerospace, automotive, and medical sectors.

2.1 Stainless Steel

Stainless steel is popular for strong, corrosion-resistant components. It’s widely used in functional prototypes, tools, and mechanical parts. 3D printing machines in 3D printing Bangalore often feature stainless steel printing capabilities.

2.2 Titanium

Titanium is lightweight, strong, and biocompatible. It’s ideal for aerospace components, medical implants, and high-performance applications. Many premium 3D printers and 3D printer services in Chennai support titanium powder printing.

2.3 Aluminum

Aluminum is lightweight, heat-resistant, and perfect for automotive and aerospace parts. Industrial 3D printing machines often provide aluminum printing services for prototyping and production.

Image Suggestion: Industrial metal 3D printer in action, printing a titanium or aluminum component.

3. Composites and Specialty Materials

Composite materials blend plastics with fibers or other additives to enhance strength, flexibility, or conductivity. These materials are ideal for specialized applications in engineering and design.

3.1 Carbon Fiber Reinforced Filaments

Carbon fiber filaments combine lightweight plastics with carbon fibers for exceptional strength and stiffness. 3D printing technology using carbon fiber is popular in aerospace, automotive, and robotics.

3.2 Wood-Filled Filaments

Wood filaments mimic the appearance and texture of real wood. They are ideal for decorative items, models, and furniture prototypes. Many 3D printer India shops provide wood-filled filaments for creative projects.

3.3 Flexible Filaments (TPU/TPE)

Flexible filaments are rubber-like, offering elasticity and impact resistance. They’re suitable for wearable items, phone cases, and seals. Low price 3D printers can often handle flexible filament printing.

3.4 Ceramic and Glass Materials

Ceramic and glass-based materials are used for heat-resistant, chemical-resistant, and artistic applications. Specialized 3D printer services near me cater to these advanced materials.

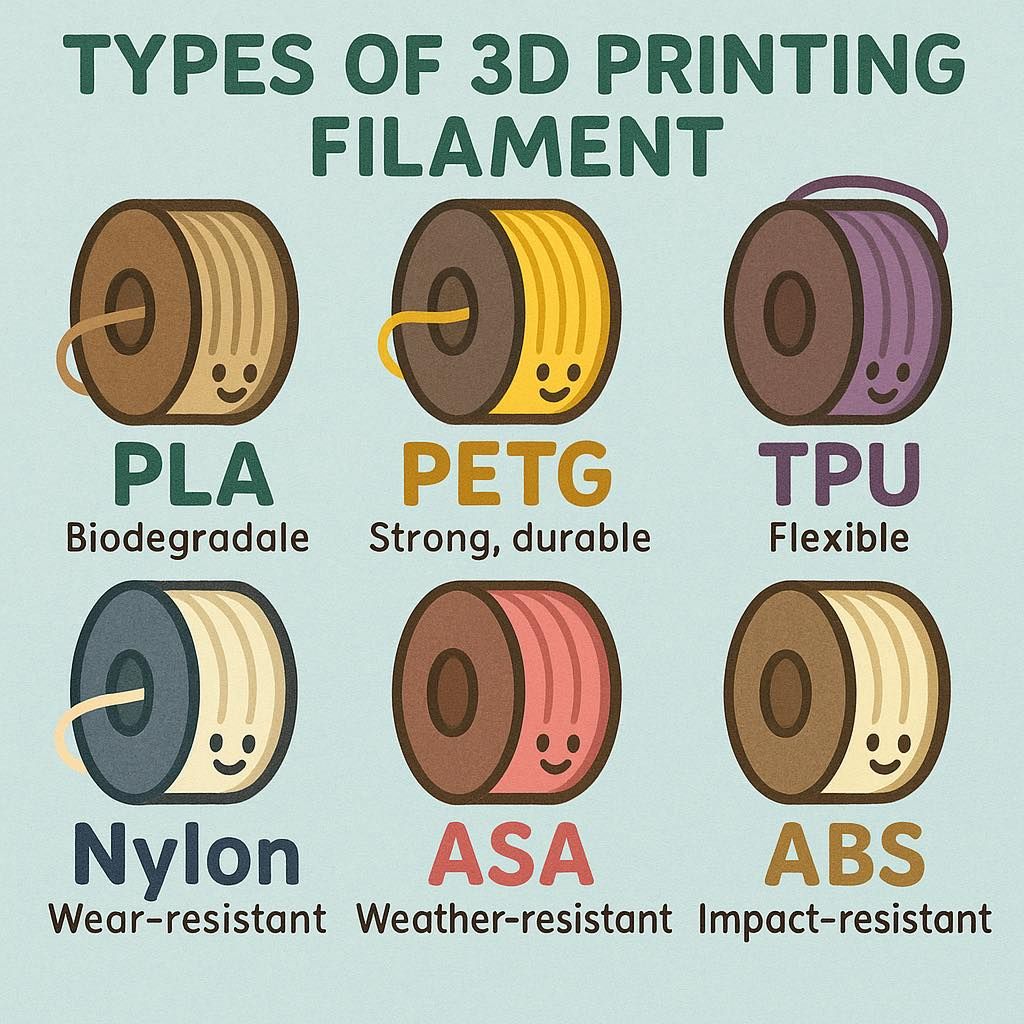

4. Types of 3D Printing Filaments

Understanding types of 3D printing filaments helps beginners and professionals choose the right material. Popular filaments include PLA, ABS, PETG, Nylon, and composites. Each filament type requires specific 3D printing software settings and 3D printing machine compatibility.

- PLA – Beginner-friendly and biodegradable

- ABS – Durable and heat-resistant

- PETG – Strong and water-resistant

- Nylon – Flexible and durable

- Composite – Carbon fiber or wood blends for enhanced performance

5. Choosing the Best Materials for 3D Printing

Selecting the best materials for 3D printing depends on your project requirements, such as strength, flexibility, heat resistance, and aesthetic finish. For hobbyists, PLA and PETG are ideal, while professionals may choose metals, composites, or specialty filaments.

When looking for 3D printing near me, check for services that offer the material you need, whether it’s plastic, metal, or composite. Online platforms to print online also provide detailed material specifications for each job.

Image Suggestion: Infographic showing different 3D printing materials with their properties and recommended applications.

6. Applications of Different 3D Printing Materials

Different materials have unique applications:

- Plastics: Prototypes, toys, educational models

- Metals: Aerospace parts, medical implants, automotive components

- Composites: High-performance engineering parts, robotics, sporting goods

- Flexible materials: Wearables, phone cases, gaskets

- Specialty materials: Art, ceramics, glass, heat-resistant components

7. Tips for Working with 3D Printing Materials

- Always use compatible 3D printing software for your material.

- Check 3D printer machine prices to ensure the machine supports your desired material.

- Consider 3D printer cost and maintenance requirements for industrial materials like metals or composites.

- Use proper post-processing techniques for strength, finish, and aesthetics.

- Look for local print shop services or online printing services for materials that are difficult to handle at home.

Conclusion

Choosing the right 3D printing materials is essential for successful additive manufacturing. Whether you are using a cheap 3D printer at home or hiring 3D printer services in Chennai, understanding plastics, metals, composites, and specialty filaments ensures the best results. By selecting appropriate materials, anyone can leverage 3D printing near me services or 3D print online to create durable, functional, and visually appealing products.

📌 Related: Types of 3D Printing Technologies

📌 Explore: Additive Manufacturing: Definition and Applications