How to Choose the Right 3D Printing Partner: Your Complete Guide

Have you ever invested time and money into a 3D printing project, only to receive disappointing results that didn’t match your expectations? Or found yourself struggling to communicate your vision to a service provider who just didn’t “get” what you were trying to achieve? If you’ve experienced the frustration of working with the wrong 3D Printing Partner, you’re not alone. Choosing the right 3D Printing Partner can mean the difference between a project that accelerates your business and one that drains your resources while delivering subpar results.

I remember working with a startup that needed functional prototypes for investor demonstrations. They chose their first 3D Printing Partner based solely on the lowest quote. The results were disastrous – poor surface finish, dimensional inaccuracies, and missed deadlines almost cost them their funding round. When they came to us, the relief was palpable. They’d learned the hard way that the cheapest 3D Printing Partner isn’t necessarily the most cost-effective one. The right 3D Printing Partner becomes an extension of your team, understanding your goals and contributing to your success.

This comprehensive guide will walk you through exactly how to choose the right 3D Printing Partner for your specific needs. Whether you’re creating one-off prototypes or establishing a long-term manufacturing relationship, these insights will help you avoid common pitfalls and build partnerships that drive your projects forward successfully.

Understanding What Makes a Great 3D Printing Partner

Before you start evaluating potential providers, it’s crucial to understand what separates an average vendor from an exceptional 3D Printing Partner.

Key Qualities of an Outstanding 3D Printing Partner

Technical Expertise:

Deep Technology Knowledge: Understands different printing technologies and their applications

Material Science Understanding: Knows which materials work best for specific requirements

Design for Additive Manufacturing: Can optimize your designs for better results

Problem-Solving Skills: Anticipates and addresses potential printing challenges

Communication and Collaboration:

Active Listening: Truly understands your project requirements and constraints

Clear Communication: Provides regular updates and manages expectations

Technical Translation: Explains complex concepts in understandable terms

Proactive Suggestions: Offers improvements and alternatives when appropriate

Assessing Your Needs Before Choosing a 3D Printing Partner

The first step in finding the right 3D Printing Partner is understanding your own requirements thoroughly.

Project Requirements Analysis

Define Your Project Scope:

Volume Needs: Are you printing single prototypes or production quantities?

Quality Expectations: What level of detail and surface finish do you require?

Material Requirements: Do you need specific mechanical or thermal properties?

Timeline Constraints: How quickly do you need results?

Technology Considerations:

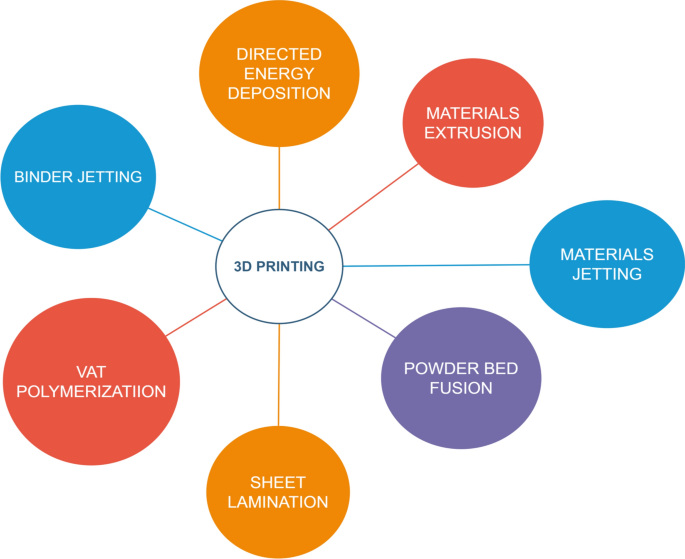

FDM: Best for functional prototypes and large parts

SLA: Ideal for high-detail models and visual prototypes

SLS: Excellent for functional parts without support structures

Metal Printing: Necessary for industrial-strength components

Key Factors in Choosing Your 3D Printing Partner

When evaluating potential 3D Printing Partner options, several critical factors should guide your decision-making process.

Technical Capabilities Assessment

Technology Portfolio:

Range of Technologies: Does they offer multiple printing methods?

Equipment Quality: Are they using industrial-grade or consumer equipment?

Material Selection: Do they have access to the materials you need?

Post-Processing Capabilities: What finishing options do they provide?

Quality Assurance:

Quality Control Processes: How do they ensure consistent results?

Measurement Equipment: Do they have tools to verify dimensional accuracy?

Documentation: Can they provide quality certifications if needed?

Consistency: Do they have processes to maintain quality across multiple prints?

Business Compatibility Factors

Communication Style:

Responsiveness: How quickly do they respond to inquiries?

Clarity: Are their communications clear and professional?

Technical Understanding: Do they grasp your project requirements quickly?

Problem-Solving Approach: How do they handle challenges or setbacks?

Business Stability:

Experience: How long have they been in business?

References: Can they provide client testimonials or case studies?

Financial Stability: Are they likely to be around for your long-term projects?

Industry Reputation: What do their customers say about them?

The Selection Process for Your 3D Printing Partner

A systematic approach to choosing your 3D Printing Partner will yield better results than making quick decisions based on limited information.

Step 1: Initial Research and Shortlisting

Identifying Potential Partners:

Online Research: Search for providers with good reviews and portfolios

Industry Recommendations: Ask colleagues for referrals

Portfolio Review: Examine their previous work for quality and relevance

Technology Match: Ensure they offer the printing methods you need

Step 2: Detailed Evaluation

Requesting and Comparing Quotes:

Provide Detailed Specifications: Clear requirements lead to accurate quotes

Compare Apples-to-Apples: Ensure quotes include all necessary services

Understand Pricing Structure: Know what’s included and what’s extra

Evaluate Value, Not Just Price: Consider quality and service alongside cost

Step 3: Capability Verification

Assessing Technical Competence:

Request Samples: Ask for physical samples of their work

Technical Discussions: Gauge their expertise through detailed conversations

Facility Visit: If possible, visit their operation to see their setup

Process Understanding: Ensure they understand your industry requirements

Red Flags When Choosing a 3D Printing Partner

Being aware of warning signs can help you avoid problematic partnerships.

Communication and Professionalism Issues

Concerning Behaviors:

Lack of Transparency: Unwilling to share processes or pricing details

Poor Communication: Slow responses or unclear answers to questions

Overpromising: Guaranteeing results that seem unrealistic

Lack of Questions: Not asking detailed questions about your requirements

Technical and Operational Concerns

Quality and Reliability Issues:

No Quality Assurance: Unable to explain their quality control processes

Limited Equipment: Relying on outdated or consumer-grade printers

No References: Unwilling or unable to provide client testimonials

Vague Timelines: Unclear about delivery schedules and capacity

Building a Successful Relationship with Your 3D Printing Partner

Once you’ve selected your 3D Printing Partner, establishing a strong working relationship is key to long-term success.

Effective Collaboration Strategies

Clear Communication Protocols:

Designated Contacts: Establish primary points of contact on both sides

Regular Updates: Set expectations for progress reporting

Feedback Loops: Create processes for providing and receiving feedback

Documentation: Maintain clear records of requirements and changes

Project Management Best Practices:

Clear Specifications: Provide detailed requirements from the start

Realistic Timelines: Agree on achievable delivery schedules

Change Management: Establish processes for handling design modifications

Quality Standards: Define acceptable quality levels and inspection methods

Evaluating Your 3D Printing Partner Over Time

A good 3D Printing Partner relationship should evolve and improve over time.

Performance Metrics to Monitor

Quality and Reliability:

On-Time Delivery: Are they meeting agreed-upon deadlines?

Quality Consistency: Is the quality consistent across multiple orders?

Problem Resolution: How effectively do they handle issues?

Continuous Improvement: Are they getting better over time?

Business Relationship Factors:

Communication Effectiveness: Is communication clear and timely?

Value for Money: Are you getting good value for your investment?

Innovation Contribution: Do they suggest improvements and new approaches?

Scalability: Can they handle your growing needs?

When to Consider Changing Your 3D Printing Partner

Sometimes, despite your best efforts, a partnership may not work out as expected.

Signs It Might Be Time for a Change

Performance Issues:

Consistent Quality Problems: Frequent defects or variations in output

Reliability Concerns: Regular missed deadlines or communication breakdowns

Lack of Improvement: No progress in addressing identified issues

Growing Costs: Prices increasing without corresponding value improvement

Strategic Misalignment:

Technology Gaps: Unable to support your evolving technical needs

Capacity Limitations: Cannot scale to meet your growing requirements

Cultural Fit Issues: Working styles or values no longer align

Innovation Stagnation: Not keeping pace with industry advancements

The Role of a 3D Printing Partner in Different Industries

Your ideal 3D Printing Partner should understand the specific requirements of your industry.

Industry-Specific Considerations

Medical and Healthcare:

Regulatory Knowledge: Understanding of medical device regulations

Biocompatible Materials: Access to approved medical-grade materials

Quality Documentation: Ability to provide necessary certifications

Patient-Specific Expertise: Experience with custom medical devices

Automotive and Aerospace:

Material Performance: Knowledge of engineering-grade materials

Testing and Validation: Understanding of industry testing requirements

Precision and Tolerance: Ability to meet tight dimensional requirements

Volume Production: Capacity for larger production runs

Consumer Products:

Aesthetic Finishing: Expertise in post-processing for visual appeal

Material Selection: Knowledge of consumer-safe materials

Cost Optimization: Ability to balance quality and cost effectively

Market Testing Support: Experience with iterative prototyping

Technology Trends Impacting 3D Printing Partner Selection

The 3D printing landscape is constantly evolving, and your 3D Printing Partner should stay current with industry developments.

Emerging Technologies to Consider

Advanced Printing Methods:

Multi-material Printing: Ability to print with multiple materials simultaneously

Continuous Printing: Systems designed for higher volume production

Hybrid Manufacturing: Combining additive and subtractive processes

Automated Post-Processing: Streamlined finishing and quality control

Digital Integration:

Online Platforms: Digital quoting and order management systems

Data Security: Protection of your intellectual property and designs

Supply Chain Integration: Ability to connect with your existing systems

Digital Inventory: Management of digital files for on-demand production

Cost Considerations When Choosing a 3D Printing Partner

While cost shouldn’t be the only factor, understanding pricing structures is essential.

Understanding Total Cost of Partnership

Direct Costs:

Printing Costs: Machine time, materials, and setup fees

Post-Processing: Additional finishing and assembly charges

Shipping and Handling: Delivery costs and packaging

Design Services: Any required design modification or optimization

Indirect Costs:

Time Savings: Value of faster iteration and time-to-market

Quality Impact: Cost of defects or rework due to poor quality

Opportunity Cost: Value lost through delays or missed opportunities

Relationship Management: Time invested in communication and coordination

Case Study: Successful 3D Printing Partner Selection

Real-world example of effective 3D Printing Partner selection and collaboration.

Medical Device Startup Success Story

Initial Challenge:

A medical device startup needed to develop and test multiple iterations of a surgical instrument prototype. They had limited budget but needed medical-grade quality and regulatory compliance support.

Selection Process:

Initial Screening: Evaluated 5 potential 3D Printing Partner options

Technical Assessment: Focused on medical industry experience and material capabilities

Quote Comparison: Balanced cost against value-added services

Reference Checks: Spoke with previous medical device clients

Partnership Outcomes:

Faster Development: Reduced prototyping cycle time by 60%

Cost Savings: 40% lower development costs than initially budgeted

Quality Results: Consistently high-quality parts that met specifications

Regulatory Success: Successfully navigated regulatory requirements

Conclusion: Making the Right Choice for Your 3D Printing Partner

Choosing the right 3D Printing Partner is one of the most critical decisions you’ll make in your additive manufacturing journey. The ideal 3D Printing Partner does more than just print your designs—they become a strategic ally who understands your business, contributes technical expertise, and helps you achieve your goals efficiently and effectively.

Remember that the cheapest option is rarely the most cost-effective in the long run. A true 3D Printing Partner invests in understanding your needs, maintains consistent quality, communicates transparently, and grows with your business. They should demonstrate technical competence, business reliability, and a commitment to your success.

As you evaluate potential 3D Printing Partner options, consider both their current capabilities and their potential for long-term partnership. The right relationship will save you time, reduce costs, improve quality, and ultimately help you leverage 3D printing technology to its fullest potential.

Ready to find your ideal 3D printing partner? Contact Arsene 3D today at +91 96295 95638 or sales@arsene3d.com for expert FDM 3D Printing in Chennai, SLA Printing in Chennai, 3D Designing services, premium filaments, and comprehensive 3D design solutions. Let’s build a successful partnership together!