Future Trends in 3D Printing: Innovations & Emerging Technologies

3D printing, also known as additive manufacturing, is rapidly evolving from a specialist technology to a mainstream industrial tool. In 2025 and beyond, this transformation is accelerating in Chennai and across the globe, spurred by advances in automation, materials science, artificial intelligence, and an expanding range of applications. From prototyping and production to education, healthcare, and infrastructure, 3D printing is reshaping industries and redefining what’s possible.

1. 3D Printing as a Standard Technology

While a decade ago, 3D printing was considered auxiliary, it’s now increasingly integrated as a routine production method. Businesses in sectors like aerospace, automotive, consumer goods, and healthcare use 3D printing for on-demand manufacturing, customization, decentralized production, and rapid prototyping. In Chennai, manufacturers, service bureaus, and local startups are adopting standardized procedures and verified materials, enabling consistent quality and safer operation—especially in critical domains.

2. Artificial Intelligence & Smart Automation

Artificial Intelligence (AI) is revolutionizing every stage of the 3D printing workflow. AI-powered software enables faster design iteration, predicts and corrects printing errors, automates quoting and material selection, and improves process reliability. For 3D printer services in Chennai, this means shorter delivery times and reduced costs for customers. AI-driven optimization also minimises waste and enhances part performance, making 3D printing a practical choice for small businesses and manufacturers.

3. Advanced Materials & Multi-Material 3D Printing

The field is witnessing breakthroughs in high-performance polymers, composites, metals, and biocompatible materials. Local services in Chennai now offer 3D printing with carbon-fiber composites, high-strength alloys, and medical-grade plastics. Multi-material 3D printers produce parts with smart features—think flexible joints, embedded electronics, and medical implants tailored to patients. The rise of printable dielectrics and functional inks is driving next-gen electronics and IoT applications .

4. Consolidation & Industry Maturity

The 3D printing industry is consolidating—smaller companies merge or exit, leaving robust players with expanded product portfolios. In Chennai, this means more reliable service providers, common standards, and wider access to state-of-the-art printers and materials. Customers enjoy improved quality control, local expertise, and better value.

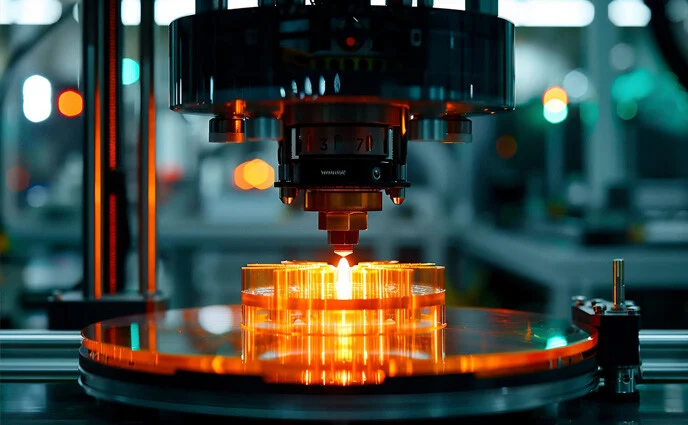

5. Automation and High-Volume Production

End-to-end automation—from digital design to finished part—enables high-volume production and works seamlessly with smart factories. Advanced printers support powder bed fusion, vat polymerization, binder jetting, and direct energy deposition. Chennai-based startups are deploying automated production lines, reducing lead times for rapid prototyping and short-run manufacturing.

6. Expansion into New Sectors & Sustainability

3D printing is expanding into precision industries (aerospace, defense, energy, semiconductors) and is essential in healthcare, education, fashion, and construction. In Chennai, hospitals use it for patient-specific implants and prosthetics, schools for STEM training, and municipality projects like 3D-printed bus shelters. These applications demonstrate the technology’s ability to reduce costs, minimize waste, and support sustainable development.

7. Bioprinting & Next-Gen Applications

Bioprinting—using biological materials to create tissues and organs—is gaining momentum. Chennai’s research hubs are exploring this for medical implants and lab models. Advanced materials like graphene open possibilities in electronics and energy storage. The convergence of 3D printing with other emerging technologies such as robotics and IoT is set to create entirely new product categories and services.

8. Growth of Service Bureaus and Localized Manufacturing

The “3D printing service near me” trend is driven by the rise of local service bureaus and distributed manufacturing hubs. In Chennai, companies like Crenodez Engineering Solutions, 3Ding, and Primaeam offer quick turnarounds for prototypes, spare parts, and custom products. Local manufacturing reduces logistics, shortens supply chains, and supports startups, artists, and SMEs in accessing affordable and advanced 3D printing.

9. 3D Printing Market Expansion & Government Support in Chennai

Chennai is experiencing rapid market expansion, supported by government incentives, innovation hubs, and industry-academia partnerships. The city’s ecosystem nurtures skilled talent, high-impact startups, and industry adoption. With over 90 3D printed bus shelters planned and ongoing investments in healthcare and education, Chennai is positioning itself as a future leader in additive manufacturing.

10. Challenges & The Road Ahead

Despite transformative potential, 3D printing faces challenges: technical limitations, regulatory standards, and high initial costs. As companies and educators overcome these barriers, the technology’s adoption will accelerate, bringing mass customization, sustainability, and new opportunities for local and global markets.

Find 3D Printing Services Near You

If you are looking for 3D printer services in Chennai or searching for “3D printing near me,” check local providers for their expertise in prototyping, production, customization, materials, and design support. Chennai’s market offers options for artists, entrepreneurs, engineers, and students.

Conclusion: A Future Shaped by 3D Printing

The future of 3D printing is bright, driven by innovation, integration with AI and automation, and new frontiers in materials and healthcare. Chennai exemplifies this evolution—with robust service providers, a dynamic startup scene, government backing, and bold new applications from art and infrastructure to medicine and manufacturing. Whether you’re an entrepreneur, engineer, artist, or student, now is the time to explore the possibilities of 3D printing and join the revolution.