Future Trends in 3D Printing: Innovations & Emerging Technologies 3D printing, also known as additive manufacturing, is rapidly evolving from a specialist technology to a mainstream industrial tool. In 2025 and beyond, this transformation is accelerating in Chennai and across the globe, spurred by advances in automation, materials science, artificial intelligence, and an expanding range of applications. From prototyping and production to education, healthcare, and infrastructure, 3D printing is reshaping industries and redefining what’s possible. 1. 3D Printing as a Standard Technology While a decade ago, 3D printing was considered auxiliary, it’s now increasingly integrated as a routine production method. Businesses in sectors like aerospace, automotive, consumer goods, and healthcare use 3D printing for on-demand manufacturing, customization, decentralized production, and rapid prototyping. In Chennai, manufacturers, service bureaus, and local startups are adopting standardized procedures and verified materials, enabling consistent quality and safer operation—especially in critical domains. 2. Artificial Intelligence & Smart Automation Artificial Intelligence (AI) is revolutionizing every stage of the 3D printing workflow. AI-powered software enables faster design iteration, predicts and corrects printing errors, automates quoting and material selection, and improves process reliability. For 3D printer services in Chennai, this means shorter delivery times and reduced costs for customers. AI-driven optimization also minimises waste and enhances part performance, making 3D printing a practical choice for small businesses and manufacturers. 3. Advanced Materials & Multi-Material 3D Printing The field is witnessing breakthroughs in high-performance polymers, composites, metals, and biocompatible materials. Local services in Chennai now offer 3D printing with carbon-fiber composites, high-strength alloys, and medical-grade plastics. Multi-material 3D printers produce parts with smart features—think flexible joints, embedded electronics, and medical implants tailored to patients. The rise of printable dielectrics and functional inks is driving next-gen electronics and IoT applications . 4. Consolidation & Industry Maturity The 3D printing industry is consolidating—smaller companies merge or exit, leaving robust players with expanded product portfolios. In Chennai, this means more reliable service providers, common standards, and wider access to state-of-the-art printers and materials. Customers enjoy improved quality control, local expertise, and better value. 5. Automation and High-Volume Production End-to-end automation—from digital design to finished part—enables high-volume production and works seamlessly with smart factories. Advanced printers support powder bed fusion, vat polymerization, binder jetting, and direct energy deposition. Chennai-based startups are deploying automated production lines, reducing lead times for rapid prototyping and short-run manufacturing. 6. Expansion into New Sectors & Sustainability 3D printing is expanding into precision industries (aerospace, defense, energy, semiconductors) and is essential in healthcare, education, fashion, and construction. In Chennai, hospitals use it for patient-specific implants and prosthetics, schools for STEM training, and municipality projects like 3D-printed bus shelters. These applications demonstrate the technology’s ability to reduce costs, minimize waste, and support sustainable development. 7. Bioprinting & Next-Gen Applications Bioprinting—using biological materials to create tissues and organs—is gaining momentum. Chennai’s research hubs are exploring this for medical implants and lab models. Advanced materials like graphene open possibilities in electronics and energy storage. The convergence of 3D printing with other emerging technologies such as robotics and IoT is set to create entirely new product categories and services. 8. Growth of Service Bureaus and Localized Manufacturing The “3D printing service near me” trend is driven by the rise of local service bureaus and distributed manufacturing hubs. In Chennai, companies like Crenodez Engineering Solutions, 3Ding, and Primaeam offer quick turnarounds for prototypes, spare parts, and custom products. Local manufacturing reduces logistics, shortens supply chains, and supports startups, artists, and SMEs in accessing affordable and advanced 3D printing. 9. 3D Printing Market Expansion & Government Support in Chennai Chennai is experiencing rapid market expansion, supported by government incentives, innovation hubs, and industry-academia partnerships. The city’s ecosystem nurtures skilled talent, high-impact startups, and industry adoption. With over 90 3D printed bus shelters planned and ongoing investments in healthcare and education, Chennai is positioning itself as a future leader in additive manufacturing. 10. Challenges & The Road Ahead Despite transformative potential, 3D printing faces challenges: technical limitations, regulatory standards, and high initial costs. As companies and educators overcome these barriers, the technology’s adoption will accelerate, bringing mass customization, sustainability, and new opportunities for local and global markets. Find 3D Printing Services Near You If you are looking for 3D printer services in Chennai or searching for “3D printing near me,” check local providers for their expertise in prototyping, production, customization, materials, and design support. Chennai’s market offers options for artists, entrepreneurs, engineers, and students. Conclusion: A Future Shaped by 3D Printing The future of 3D printing is bright, driven by innovation, integration with AI and automation, and new frontiers in materials and healthcare. Chennai exemplifies this evolution—with robust service providers, a dynamic startup scene, government backing, and bold new applications from art and infrastructure to medicine and manufacturing. Whether you’re an entrepreneur, engineer, artist, or student, now is the time to explore the possibilities of 3D printing and join the revolution.

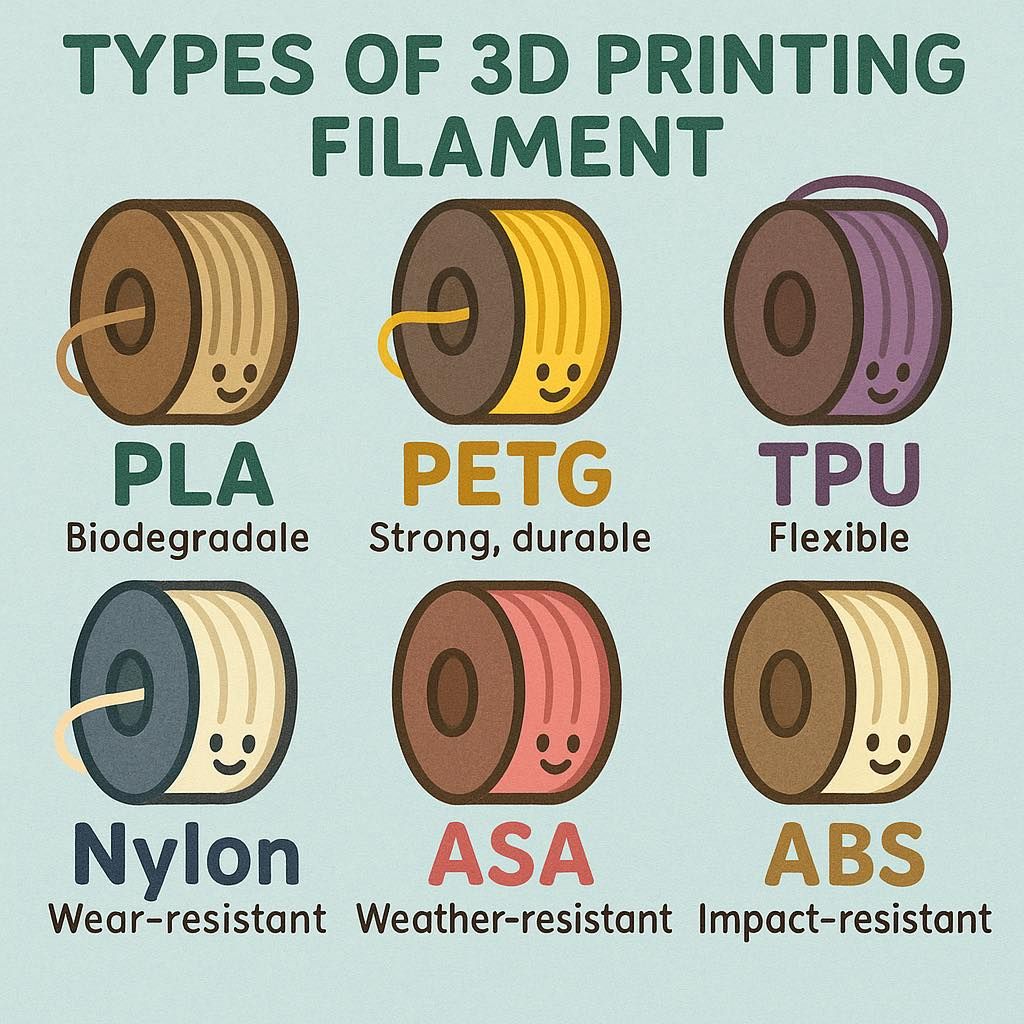

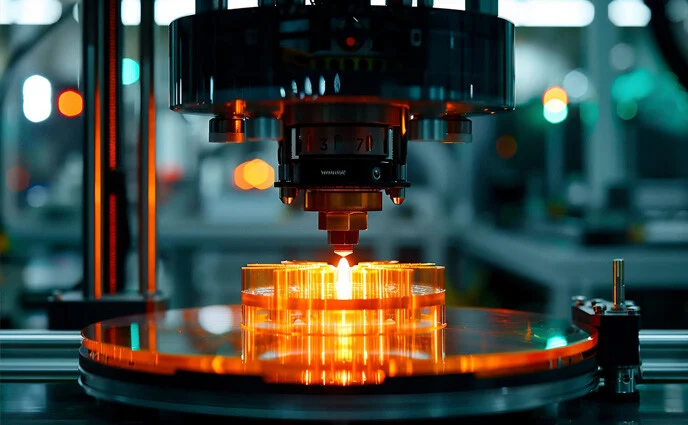

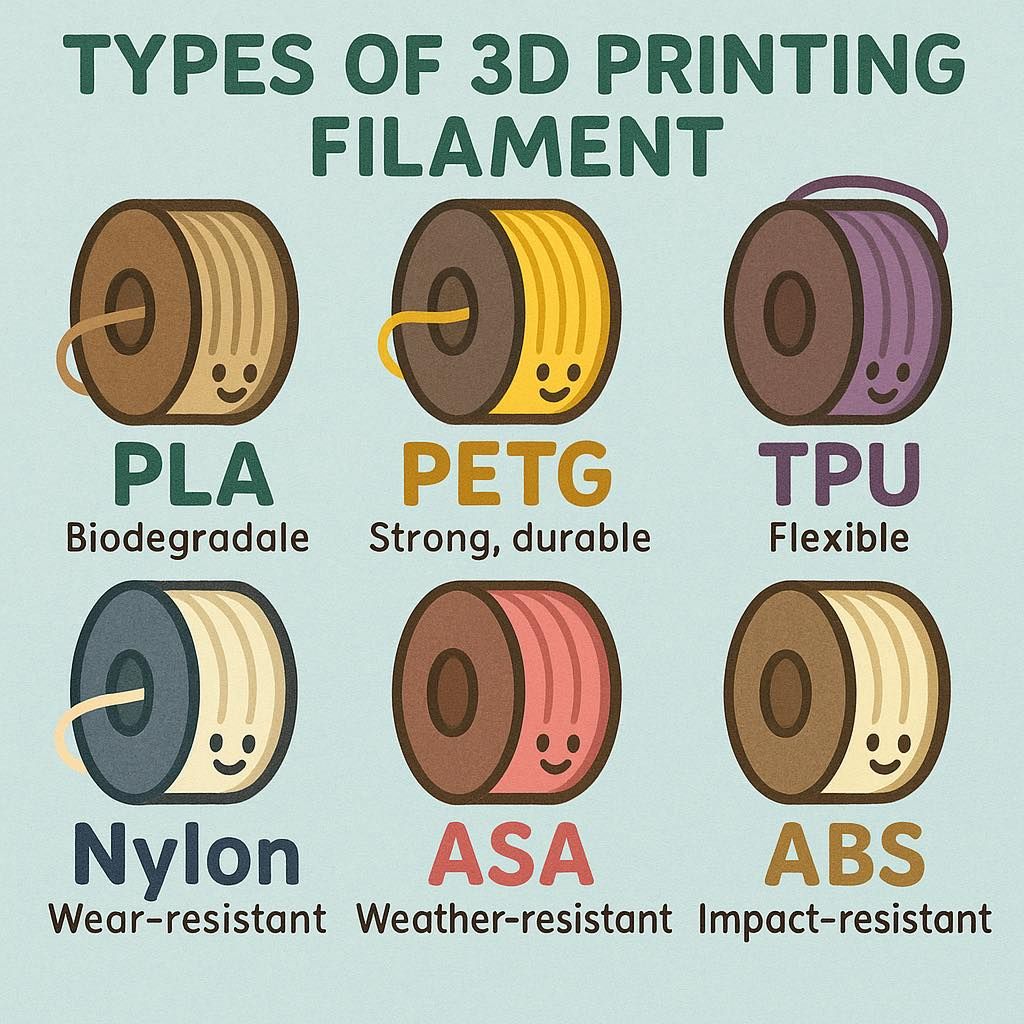

The success of 3D printing depends heavily on the materials used. 3D printing materials determine the strength, flexibility, durability, and overall functionality of the final product. From hobbyists using 3D printer services in Chennai to industrial applications worldwide, choosing the right material is crucial for every 3D printing project. 1. Plastics: The Most Common 3D Printing Materials Plastics are the backbone of 3D printing technology, widely used by both beginners and professionals. Their versatility and low cost make them ideal for prototypes, models, and functional parts. Some popular types include: 1.1 PLA (Polylactic Acid) PLA is a biodegradable thermoplastic made from renewable resources like corn starch. It’s one of the easiest materials to print with and is often recommended for beginners using 3D printers. 3D printing near me shops often stock PLA due to its popularity. 1.2 ABS (Acrylonitrile Butadiene Styrene) ABS is stronger and more heat-resistant than PLA. It’s ideal for functional parts like casings and automotive components. Many 3D printer services near me provide ABS printing because of its industrial applications. 1.3 PETG (Polyethylene Terephthalate Glycol) PETG combines strength, flexibility, and chemical resistance. It’s suitable for water-resistant parts and functional prototypes. Online platforms for 3D print online often offer PETG as a standard option. 1.4 Nylon Nylon is highly durable, flexible, and abrasion-resistant. It is commonly used in mechanical parts, gears, and wearable items. 3D printing Chennai services often recommend nylon for demanding applications. 2. Metals in 3D Printing Metal 3D printing materials are used in industries requiring high strength, durability, and precision. Metal additive manufacturing is prevalent in aerospace, automotive, and medical sectors. 2.1 Stainless Steel Stainless steel is popular for strong, corrosion-resistant components. It’s widely used in functional prototypes, tools, and mechanical parts. 3D printing machines in 3D printing Bangalore often feature stainless steel printing capabilities. 2.2 Titanium Titanium is lightweight, strong, and biocompatible. It’s ideal for aerospace components, medical implants, and high-performance applications. Many premium 3D printers and 3D printer services in Chennai support titanium powder printing. 2.3 Aluminum Aluminum is lightweight, heat-resistant, and perfect for automotive and aerospace parts. Industrial 3D printing machines often provide aluminum printing services for prototyping and production. Image Suggestion: Industrial metal 3D printer in action, printing a titanium or aluminum component. 3. Composites and Specialty Materials Composite materials blend plastics with fibers or other additives to enhance strength, flexibility, or conductivity. These materials are ideal for specialized applications in engineering and design. 3.1 Carbon Fiber Reinforced Filaments Carbon fiber filaments combine lightweight plastics with carbon fibers for exceptional strength and stiffness. 3D printing technology using carbon fiber is popular in aerospace, automotive, and robotics. 3.2 Wood-Filled Filaments Wood filaments mimic the appearance and texture of real wood. They are ideal for decorative items, models, and furniture prototypes. Many 3D printer India shops provide wood-filled filaments for creative projects. 3.3 Flexible Filaments (TPU/TPE) Flexible filaments are rubber-like, offering elasticity and impact resistance. They’re suitable for wearable items, phone cases, and seals. Low price 3D printers can often handle flexible filament printing. 3.4 Ceramic and Glass Materials Ceramic and glass-based materials are used for heat-resistant, chemical-resistant, and artistic applications. Specialized 3D printer services near me cater to these advanced materials. 4. Types of 3D Printing Filaments Understanding types of 3D printing filaments helps beginners and professionals choose the right material. Popular filaments include PLA, ABS, PETG, Nylon, and composites. Each filament type requires specific 3D printing software settings and 3D printing machine compatibility. PLA – Beginner-friendly and biodegradable ABS – Durable and heat-resistant PETG – Strong and water-resistant Nylon – Flexible and durable Composite – Carbon fiber or wood blends for enhanced performance 5. Choosing the Best Materials for 3D Printing Selecting the best materials for 3D printing depends on your project requirements, such as strength, flexibility, heat resistance, and aesthetic finish. For hobbyists, PLA and PETG are ideal, while professionals may choose metals, composites, or specialty filaments. When looking for 3D printing near me, check for services that offer the material you need, whether it’s plastic, metal, or composite. Online platforms to print online also provide detailed material specifications for each job. Image Suggestion: Infographic showing different 3D printing materials with their properties and recommended applications. 6. Applications of Different 3D Printing Materials Different materials have unique applications: Plastics: Prototypes, toys, educational models Metals: Aerospace parts, medical implants, automotive components Composites: High-performance engineering parts, robotics, sporting goods Flexible materials: Wearables, phone cases, gaskets Specialty materials: Art, ceramics, glass, heat-resistant components 7. Tips for Working with 3D Printing Materials Always use compatible 3D printing software for your material. Check 3D printer machine prices to ensure the machine supports your desired material. Consider 3D printer cost and maintenance requirements for industrial materials like metals or composites. Use proper post-processing techniques for strength, finish, and aesthetics. Look for local print shop services or online printing services for materials that are difficult to handle at home. Conclusion Choosing the right 3D printing materials is essential for successful additive manufacturing. Whether you are using a cheap 3D printer at home or hiring 3D printer services in Chennai, understanding plastics, metals, composites, and specialty filaments ensures the best results. By selecting appropriate materials, anyone can leverage 3D printing near me services or 3D print online to create durable, functional, and visually appealing products. 📌 Related: Types of 3D Printing Technologies 📌 Explore: Additive Manufacturing: Definition and Applications

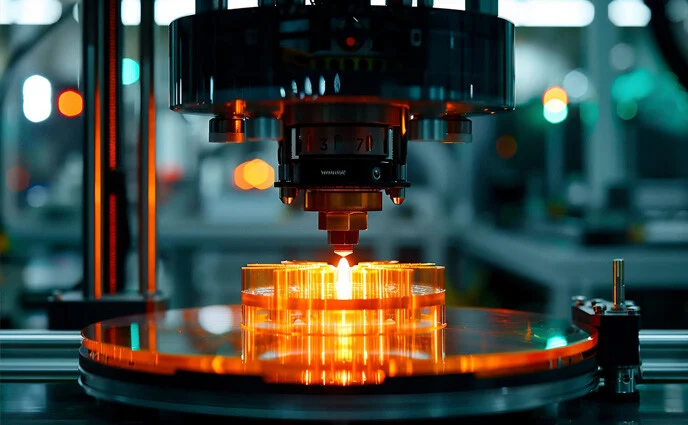

Additive Manufacturing: Definition and Applications Additive manufacturing, often called 3D printing, is a process of creating objects layer by layer directly from a digital model. Unlike traditional subtractive methods, additive manufacturing builds the product using materials such as plastics, resins, or metals, offering precision, speed, and flexibility. Definition of Additive Manufacturing The additive manufacturing definition refers to the process of producing three-dimensional objects from computer-generated designs using 3D printing machines. Each layer is added sequentially, which allows complex geometries that are difficult or impossible with conventional manufacturing methods. Applications of Additive Manufacturing The applications of additive manufacturing are vast and span multiple industries. It is not just for prototypes; many companies now use 3D printing for end-use parts, tooling, and even mass customization. Automotive Industry: Creating lightweight components, custom parts, and prototypes. Aerospace Industry: Producing complex engine parts, brackets, and lightweight structures. Healthcare: Designing surgical tools, implants, and dental devices using 3D printing software. Education and Research: Students and researchers use 3D printers to experiment with designs and models. Consumer Products: Customized footwear, fashion accessories, and electronics components. Industries Using 3D Printing Various industries using 3D printing are rapidly adopting additive manufacturing for faster production, reduced costs, and enhanced innovation. From 3D printing in Chennai to global manufacturing hubs, businesses are integrating 3D printing into their workflows. Some key industries include: Aerospace & Defense Automotive & Transportation Medical & Dental Consumer Goods Architecture & Construction Advantages of Additive Manufacturing Using 3D printing machines and 3D printing technology provides several advantages: Ability to create complex and customized designs Reduced material waste compared to traditional methods Faster prototyping and production cycles Cost-effective for small batch production Access to online printing services and 3D print online platforms Conclusion The potential of additive manufacturing extends across numerous sectors, from industrial applications to personalized consumer products. Understanding the additive manufacturing definition and exploring its applications helps businesses and individuals leverage the power of 3D printing services and stay ahead in innovation. 📌 Related: Types of 3D Printing Technologies 📌 Explore: 3D Printing Basics: A Complete Guide

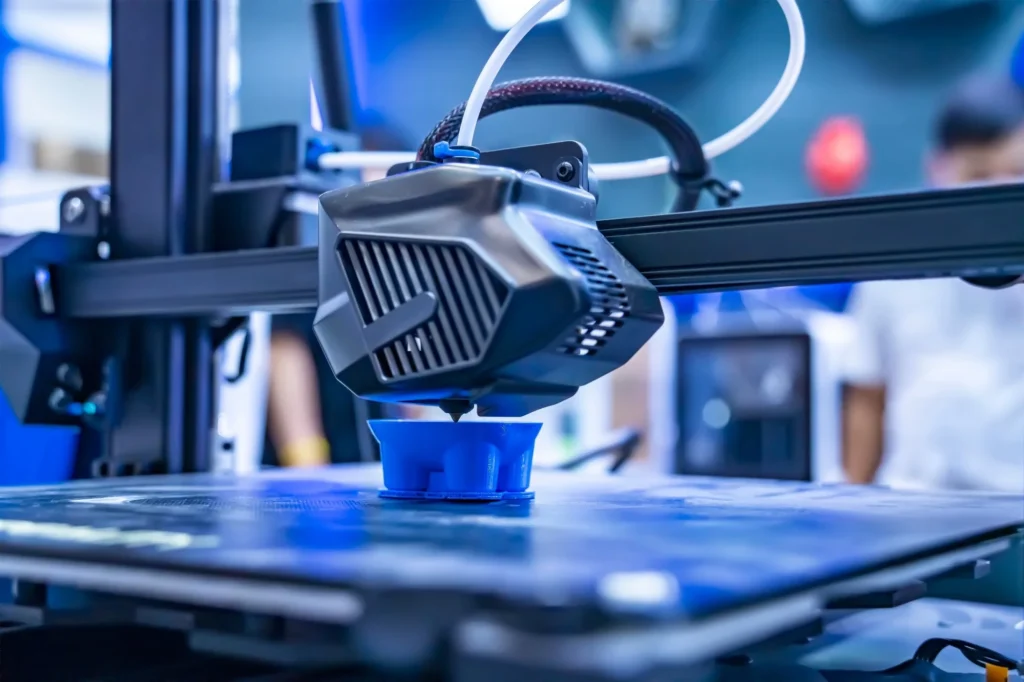

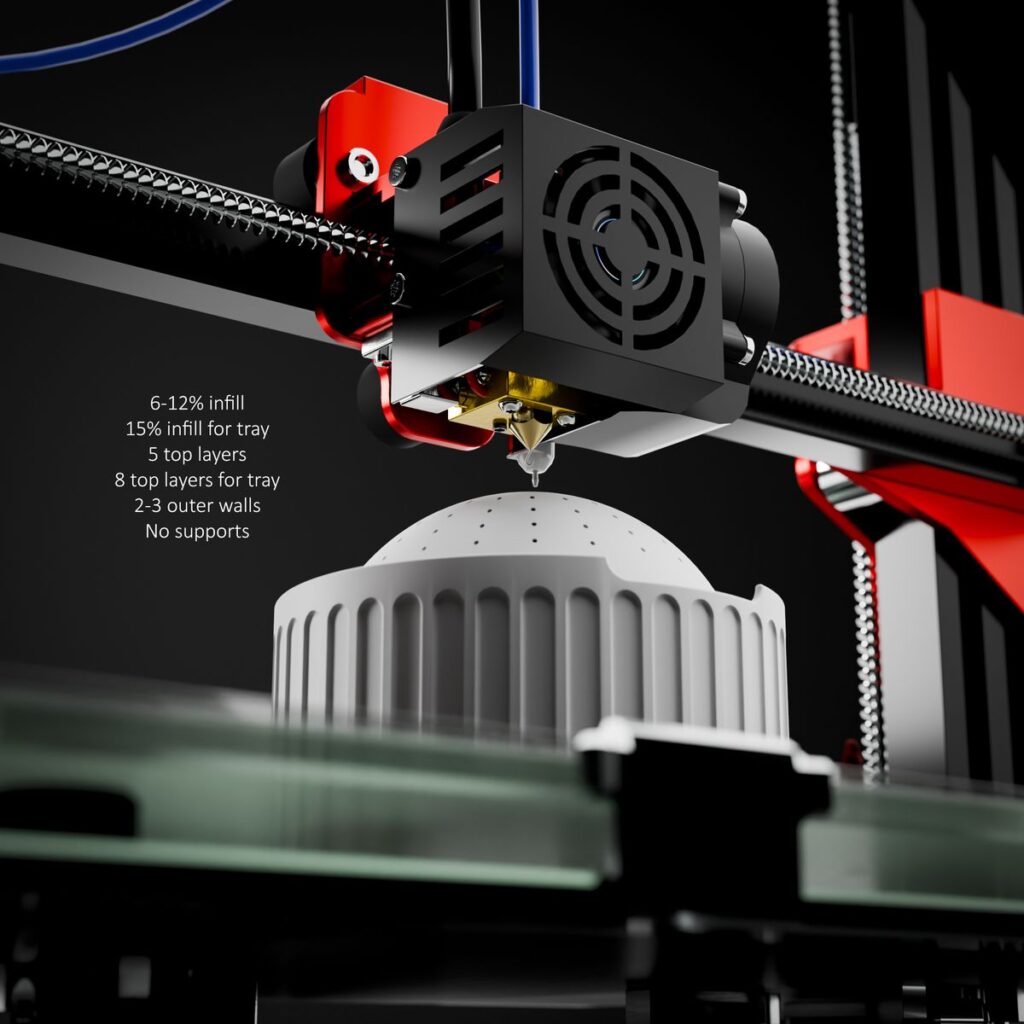

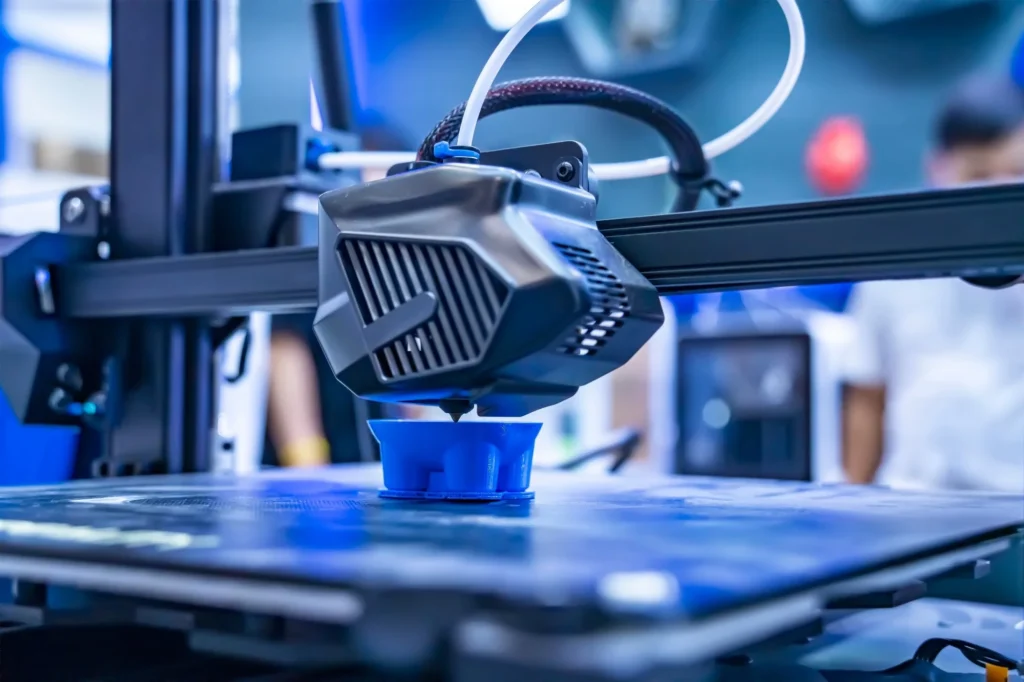

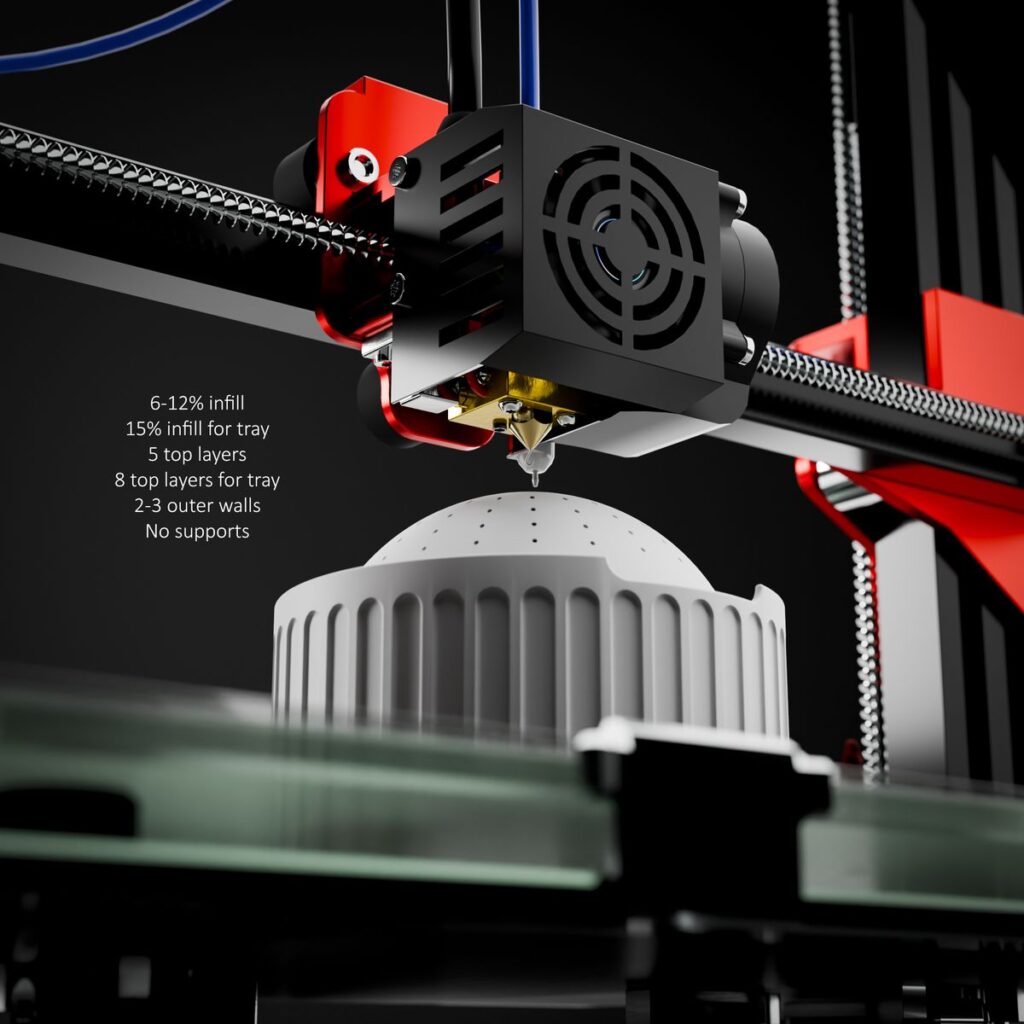

Types of 3D Printing Technologies If you are searching for 3D printing near me or exploring 3D printer services, it’s important to understand the different types of 3D printing available. Each 3D printing technology has unique strengths and limitations, making it suitable for different applications. Whether you’re in Chennai or ordering 3D printing online, knowing the options helps you choose the right service. 1. FDM (Fused Deposition Modeling) FDM is the most popular 3D printing technology for both beginners and professionals. It works by extruding melted filament layer by layer to build the object. Advantages include affordability, ease of use, and compatibility with a wide range of 3D printers. However, the surface finish may be rougher compared to other technologies. Pros of FDM: Low-cost and widely available 3D printer machines Easy to operate and maintain Great for prototypes and functional parts Cons of FDM: Lower detail resolution Surface finish may require post-processing 2. SLA (Stereolithography) SLA 3D printers use a laser to cure liquid resin into solid layers. This technology produces highly detailed prints, making it ideal for jewelry, dental models, and intricate prototypes. In comparison with FDM, SLA provides smoother finishes and finer details. Pros of SLA: High precision and smooth surface finish Excellent for detailed models and prototypes Cons of SLA: Higher 3D printer cost than FDM Requires post-processing like washing and curing 3. SLS (Selective Laser Sintering) SLS uses a laser to sinter powdered material, creating objects without needing support structures. It is popular for industrial applications and functional prototypes. While 3D printer machines for SLS are expensive, the technology allows complex geometries and durable parts. Pros of SLS: Supports complex and durable designs No need for support structures Cons of SLS: High cost of 3D printing machines and materials Requires specialized knowledge to operate FDM vs SLA: Choosing the Right Technology When comparing FDM vs SLA, the choice depends on your project requirements. FDM is cost-effective and suitable for functional prototypes, while SLA is perfect for highly detailed, visually appealing models. For a professional 3D printing service near me in Chennai, providers usually offer both options to meet different needs. Other 3D Printing Technologies Besides FDM, SLA, and SLS, there are other 3D printing technologies like DLP (Digital Light Processing) and MJF (Multi Jet Fusion). These methods are often used for specialized industrial applications, offering speed and precision. For beginners and small businesses, understanding the options helps in choosing the right 3D printing service or nearest printing shop. Image suggestion: FDM 3D printer creating a simple model. Image suggestion: SLA 3D printer producing a highly detailed prototype. Image suggestion: Industrial SLS 3D printing machine in action. Conclusion Understanding the types of 3D printing technologies is crucial whether you are looking for a 3D printer in Chennai, searching for 3D printing near me, or planning to use 3D print online. Knowing the differences between FDM, SLA, SLS, and other technologies ensures you pick the right 3D printer service or print shop for your project. 📌 Read more: 3D Printing Basics: A Complete Guide 📌 Related: Best 3D Printers for Your Needs

3D Printing Explained: Key Concepts and Terms When people search for 3D printing near me or explore options like 3D printer service, they often come across technical words that can feel overwhelming. This guide explains the most important 3D printing glossary terms to help beginners and professionals understand the technology better. Whether you are looking for 3D printing in Chennai, 3D printing service near me, or exploring how a 3D printer works, these terms will simplify your journey. What is 3D Printing? 3D printing, also known as additive manufacturing, is the process of creating physical objects layer by layer using a digital model. If you search for a 3D printing service near me, you’ll find companies that use advanced 3D printing machines to turn your ideas into reality. In cities like Chennai, 3D printing in Chennai has become increasingly popular for prototyping, education, and industrial uses. Key 3D Printing Terms and Concepts 1. CAD (Computer-Aided Design) Most 3D printing projects start with a digital design made using 3D software. This includes tools like CAD programs where a 3D model maker creates a digital blueprint. Beginners often start with simple 3D sketches before advancing to professional 3D designs. 2. STL File The STL file is one of the most common formats for 3D models. If you’re using a 3D printing service near me or searching for 3D print online, you’ll likely be asked to upload an STL file for processing. 3. FDM (Fused Deposition Modeling) FDM 3D printing is the most widely used technology for beginners because it’s affordable and supported by the best 3D printers in the market. It’s also popular in local hubs like 3D printing Chennai and 3D printing Bangalore where startups and professionals use it for rapid prototyping. 4. SLA (Stereolithography) An SLA 3D printer uses light to cure liquid resin into solid layers. This method delivers highly detailed models and is commonly used in industries such as jewelry and healthcare. If you’re exploring professional 3D printing services, SLA is often recommended. 5. Print Bed The print bed is the flat surface where objects are created. Whether you buy a cheap 3D printer, a low price 3D printer, or a premium 3D printing machine, a stable print bed is essential for accuracy. 6. Slicing Software 3D printing software called a slicer converts your 3D design into instructions that a 3D printer can follow. This is an important step in the 3D printing process for both home setups and professional 3D printer services. Why Understanding These Terms Matters Knowing these 3D printing concepts makes it easier to work with a 3D printing service near me, whether you’re in Chennai, Bangalore, or ordering a 3D print online. It also helps when comparing options like 3D printer price in India, 3D printer cost, or exploring 3D printer India suppliers. Where to Start? If you’re new to the field, begin with an affordable 3D printer or try a local 3D printer service. Searching for 3D printing near me will show nearby print shops, printing services, and even online printing services where you can print online with ease. In Chennai, for example, 3D printing in Chennai is supported by many modern nearest printing shops and professional providers. Conclusion Understanding key 3D printing terms is the first step toward becoming confident with the technology. Whether you’re researching 3D printer price, seeking a 3D printing service near me, or planning to invest in 3D printing in Chennai, knowing this glossary will make your journey easier and more effective. 📌 Read more: 3D Printing Basics: A Complete Guide 📌 Related: How Does 3D Printing Work?

3D printing, also known as additive manufacturing , has transformed the way we create prototypes, models, and even end-use products. Whether you’re searching for 3D printing near me, planning to 3D print online, or exploring the best 3D printer in India, understanding the 3D printing process is the first step. This guide explains how 3D printing technology works, the role of 3D design and software, and the machines that make it possible. Step 1: Creating the 3D Design Every project begins with a 3D design. Designers use tools such as CAD (Computer-Aided Design) or specialized 3D software to create a virtual model. Whether you’re working with a professional 3D model maker or sketching your own concept using 3D sketch programs, this is the foundation of the printing process. Many online printing services also provide design assistance to help beginners get started. Step 2: Slicing the Model with 3D Printing Software Once the design is ready, it must be processed using 3D printing software. This step is called “slicing,” where the model is divided into thin layers that a 3D printer can read. Whether you’re planning to use FDM 3D printing or advanced methods like SLA 3D printing, slicing ensures your design is converted into instructions that guide the 3D printing machine. Step 3: Setting Up the 3D Printer Now comes the exciting part—setting up the 3D printer. Depending on your needs, you might look for a cheap 3D printer for home projects or a professional-grade machine from a print shop. Businesses in cities like 3D printing Bangalore often provide access to advanced machines without the upfront 3D printer cost. The 3D printer price in India varies, ranging from a low price 3D printer for hobbyists to industrial 3D printing machine price options for companies. Step 4: Printing the Object When the machine starts, the 3D printing technology builds the model layer by layer. In FDM 3D printing, melted plastic filament is deposited to form the structure. In SLA 3D printing, liquid resin is cured using lasers. Choosing the best 3D printer depends on your purpose—home projects, medical applications, or industrial production. For those searching for 3D printing service near me, local providers can deliver quality prints without you needing to invest in a machine. Step 5: Post-Processing and Finishing After printing, the object often requires post-processing. This may include removing supports, sanding, or polishing for a smooth finish. Many printing services or nearest printing shop providers handle this step for clients. If you print online, service providers ensure the product is finished and ready for delivery. This makes online printing services a great choice for small businesses, startups, and students. Why 3D Printing Matters Today Understanding how 3D printers work highlights why they are changing industries. From low-cost prototyping to medical innovations, the flexibility of 3D printing machines makes them invaluable. For students, hobbyists, and businesses, exploring 3D printing near me or checking 3D printer price in India helps decide whether to buy or outsource to a print shop. Either way, the future of 3D printing technology looks bright. Final Thoughts The steps of 3D printing —from design, slicing, and setup to printing and finishing—make it clear why this technology is revolutionizing manufacturing. Whether you’re a student searching for a low price 3D printer, a business comparing 3D printing machine prices, or an entrepreneur working with online printing services, knowing how the process works helps you make smarter decisions. Start experimenting today with 3D design software, or connect with a 3D printing service near me to bring your ideas to life.